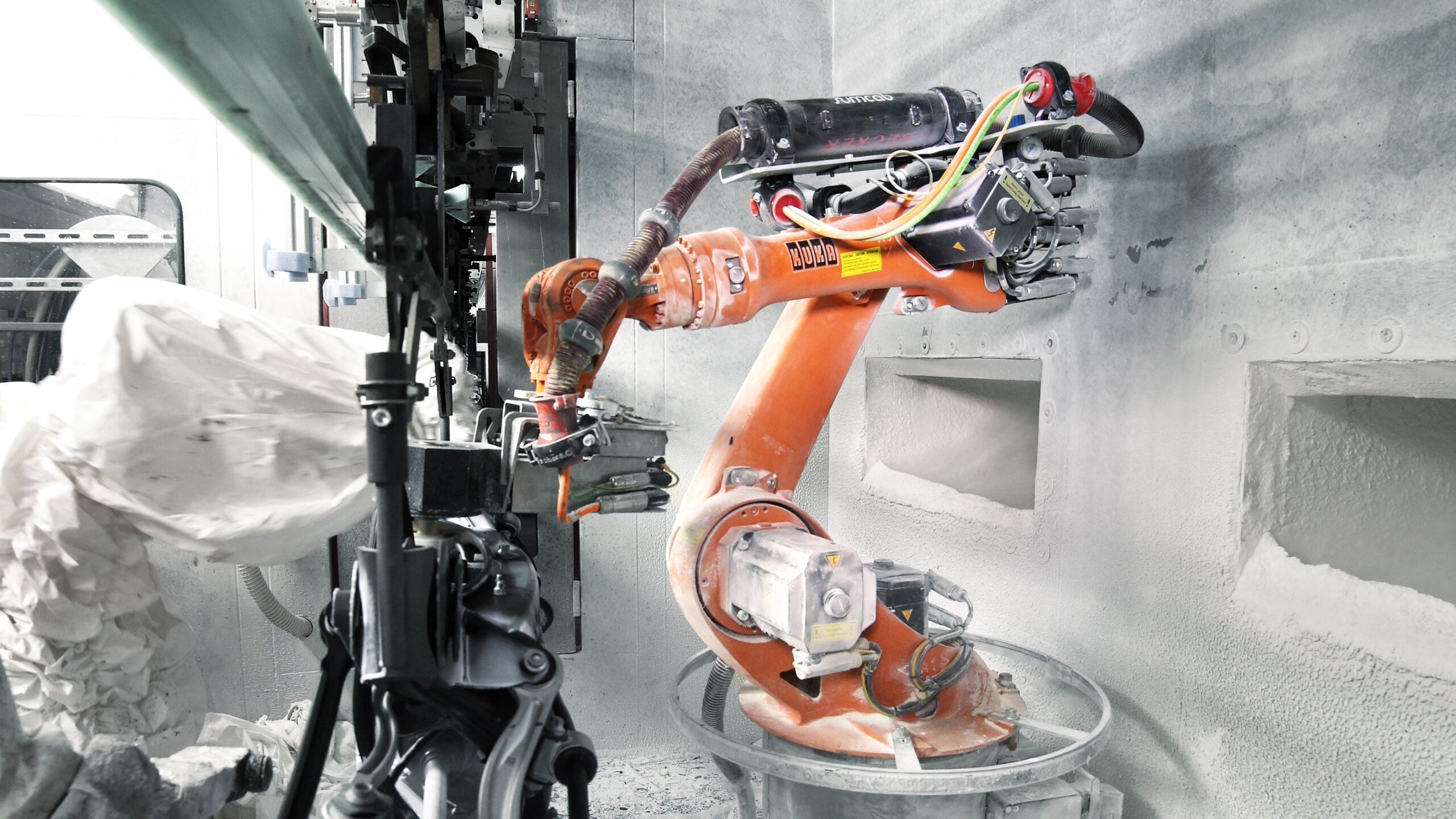

Robot Process Setup

Robotic industrial automation is changing the face of manufacturing. Manufacturers around the world are implementing some form of automation to become more efficient, secure and ultimately increase revenues. While some advantages are obvious, there may be more to it than you think. Put it all together and you can see why so many industries are investing in industrial robots.

Advantages of Robots in Industrial Automation:

Quality control - No one likes to buy a product, only the poor quality disappoints. Robots are a great solution for higher quality production. Quality builds trust from customers and takes pride in knowing that you are contributing something of value.

Repeatability - Being consistent and knowing that you will get the same quality end product is essential for productivity. A robot can perform the same task over and over in exactly the same way. Fewer mistakes means less time wasted.

Waste Reduction - Consistent repeatability allows manufacturers to reduce overall waste. Fewer mistakes not only save time, but also reduce the amount of material needed to manufacture the product. A few examples: robots can use less wire to weld, use less paint, and cut closer to the edge.

Faster Cycle Times - Unfortunately, people have their own limits. Robots are known to greatly improve production cycle speeds. The more you can produce, the more you can meet the higher demand and ultimately make more money.

Enhanced Workplace Safety - There are many dangerous working environments that can have horrendous side effects on a human body. Separating workers from lifting too much weight, exposure to fumes and gas, and close interaction with lasers or blades can greatly reduce the chance of injury.

Reducing Labor Costs - Labor can be expensive, especially if it includes medical benefits, paid leave, injury compensation time, etc. If you take into account ... Robots can replace certain jobs, but that doesn't mean they're going to take over the world. It just means we have to adjust our focus. Understanding that robots are there for our own safety and productivity allows us to move workers from difficult and boring jobs to more fulfilling roles.

Reduced Floor Area - It's easy to get started in the workshop with extra supplies, tools and machines. Robots can help reduce the footprint of the required workspace by optimizing everything into a smaller, confined space.

Integration with Business Systems - Today, communication between multiple data platforms is growing rapidly and increasing efficiency. You can see when a bottleneck is much faster when the appropriate technology is installed. Robots and machines talk to each other to give business leaders a better view of the overall picture, helping them make smarter decisions about how to improve their processes.

All these advantages help companies stay competitive in a global economy. You may think that buying a robot is outside of your budget or knowledge. However, several options and support are available to reduce startup costs and get you up and running in no time. Experience working with a variety of small and large production facilities doğru entegratörle can greatly help your business success.

Applications:

- Assembly & Transfer

- Palletizing & Packaging

- Camera & Vision

- Waterjet Automation

- Spot Welding

- Arc Welding

- Polishing & Grinding & Sanding

- Laser Cutting and Plasma Cutting

- Painting and Spraying

- Press Brake Feeding

- 2D / 3D Machining

- Flaring and Plasma

- Sealant & Bonding